Sales

08:00~24:00

Jiangsu Zhongzhilian Steel Industry Co., Ltd.,

Contact person: sales

Tel:+86-13373608768

Email:sales@zzlsteel.com

What’app: 0086-13373608768

Skype:0086-13373608768

Wechat : 0086-13373608768

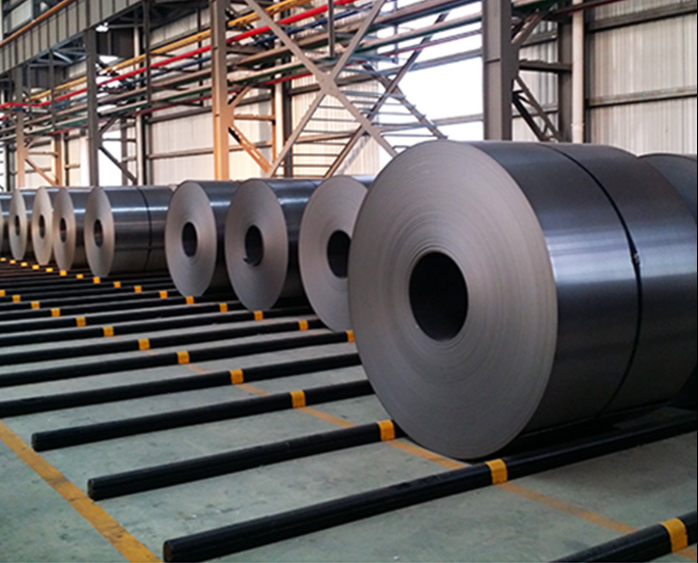

Electrical steel usually referred to as cold-rolled electrical steel, can be divided into two major categories including grain-oriented electrical steel and non-oriented electrical steel. Grain-oriented electrical steel, with its easy magnetization direction parallel to the rolling direction, has excellent magnetic properties in this direction including low core loss, high permeability, and low magnetostriction, and is widely used in the transformer industry. Further, it can obtain lower core loss by domain refinement treatment. Meanwhile, non-oriented electrical steel, featured by a random distribution of grain orientation and magnetic isotropy, is widely applicable to the motor industry.

The grain-oriented silicon steel is a kind of electrical steel with its easy magnetization direction parallel to the rolling direction and a silicon content of around 3%. The grain-oriented silicon steel can be divided into two major categories including common grain-oriented silicon steel and high magnetic induction grain-oriented silicon steel. It is mostly applicable to the field of power transmission (such as transformers) and is an important functional metal material in the electrical power, electronic and military industries.

Grain-orientedsilicon steel has long been known as the art work of steel, which are technologically sophisticated and technically complicated. Whether to master the technology for producing the grain-oriented silicon steel has always been used as an indicator of a steel manufacturer’s technological capability.

Features of Silicon Steel

Great Electromagnetic Performance

The silicon steel comes with low iron loss and high magnetic induction, especially HiB steel which has lower iron loss and higher magnetic induction.

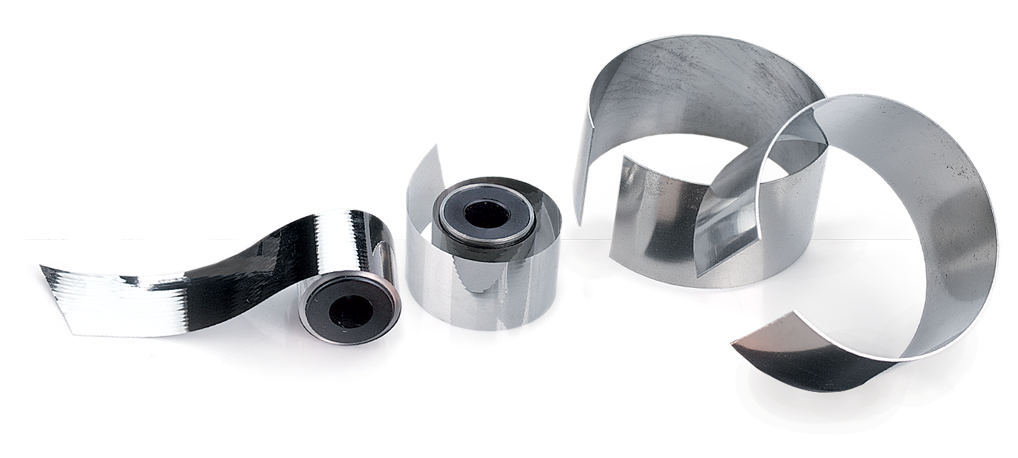

Good Shape

The material is often made in strips. Slight longitudinal and transverse thickness difference ensures a high lamination factor.

Insulating Coating

Uniform color, excellent insulative, high adhesion strength, high heat resistance, excellent processability, and superior corrosion resistance. Our silicon steel sheet is available in multiple insulating coating options, which have been reaching and RoHS certified that harmful matter content complies with domestic and overseas regulations on environmental protection.

Excellent Processability

Accessible to die-cut, with high dimensional accuracy.

Surface Quality

Our silicon steel features a smooth surface, without defects such as rust, rolling marks, holes, cold-lap,folds, bubbles, etc

Mechanical Property

|

Mechanical Property |

||||

|

Grade |

Yeild Strength |

Ultra |

Ductility |

Hardness |

|

M35W230 |

430 |

560 |

20.0 |

225 |

|

M35W250 |

415 |

550 |

20.5 |

220 |

|

M35W270 |

400 |

515 |

20.5 |

215 |

|

M35W300 |

360 |

480 |

21.5 |

195 |

|

M35W360 |

350 |

480 |

23.5 |

190 |

|

M35W440 |

275 |

420 |

27.5 |

165 |

|

M35W550 |

265 |

415 |

33.5 |

160 |

|

M50W250 |

430 |

560 |

19.0 |

230 |

|

M50W270 |

410 |

550 |

21.5 |

225 |

|

M50W290 |

395 |

545 |

22.5 |

220 |

|

M50W310 |

385 |

510 |

24.5 |

210 |

|

M50W350 |

350 |

475 |

26.5 |

190 |

|

M50W400 |

320 |

460 |

36.0 |

170 |

|

M50W470 |

295 |

425 |

35.0 |

160 |

|

M50W600 |

280 |

410 |

37.0 |

140 |

|

M50W800 |

285 |

405 |

38.5 |

135 |

|

M50W1300(D) |

250 |

360 |

40.0 |

115 |

Insulating Coating

|

Insulating Coating |

||

|

Coating types |

M11 |

M21 |

|

Component |

Chromium containing , semi organic coating |

Chromium free, semi organic coating |

|

Coating thickness(μm) |

0.7~1.5 |

0.8~5.0 |

|

Interlayer resistance |

≥100 |

≥100 |

|

Adhesive property |

Class A or class B |

Class A or class B |

|

Punching property |

Excellent |

Excellent |

|

Antirust property |

Excellent |

Excellent |

|

Heat resisting property |

Resistant annealing at 750 C, N2 protection, for 2h |

Annealing resistance in general |

Fields of Application

|

Fields of application |

Grain-oriented electrical steel |

Non-oriented electrical steel |

|||||||||

|

Series G |

Series P |

Series R |

Series A |

Series AH |

Series AR |

Series AT |

|||||

|

230~400 |

440~700 |

800~1300 |

230~470 |

600~1000 |

|||||||

|

Rotators |

Large-sized motors |

√ |

|

|

√ |

|

|

|

|

|

|

|

Medium-sized motors |

|

|

|

√ |

√ |

|

√ |

|

|

|

|

|

Compressor motors |

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

General motors |

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

Small-sized precision motors |

|

|

|

√ |

√ |

√ |

√ |

|

√ |

√ |

|

|

Motors for electric cars |

|

|

|

√ |

|

|

√ |

|

√ |

√ |

|

|

Static device |

High-frequency motors |

|

|

|

√ |

|

|

√ |

|

|

√ |

|

Large-sized transformers |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

Small-sized power transformers |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

Transformers for instruments |

√ |

√ |

|

√ |

|

|

|

|

|

|

|

|

Reactors and magnetic amplifiers |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

Power switches |

|

|

|

√ |

|

|

|

|

|

|

|

|

Transformers for welding |

|

|

|

|

√ |

√ |

|

√ |

|

|

|

|

Voltage regulators |

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

Magnetic sealers |

√ |

√ |

|

√ |

√ |

|

|

|

|

|

|

|

Electromagnetic devices for accelerators |

√ |

√ |

|

|

√ |

|

√ |

|

|

|

|

Material Selection - Grain-oriented electrical steel

|

Varieties |

Common type |

High induction type |

Domain refined |

|

Large motors |

√ |

√ |

|

|

Large transformers |

√ |

√ |

√ |

|

Medium and small transformers |

√ |

√ |

√ |

|

Distributing transformers |

√ |

√ |

|

|

Voltage regulator |

√ |

√ |

√ |

|

Reactor and magnetic amplifier |

√ |

√ |

|

|

IF transformer |

|

√ |

|

|

Mutual inductor |

√ |

√ |

|

|

TV transformer |

√ |

√ |

|

|

Radio transformer |

√ |

√ |

|

|

Radio broadcast transformer |

|

√ |

|

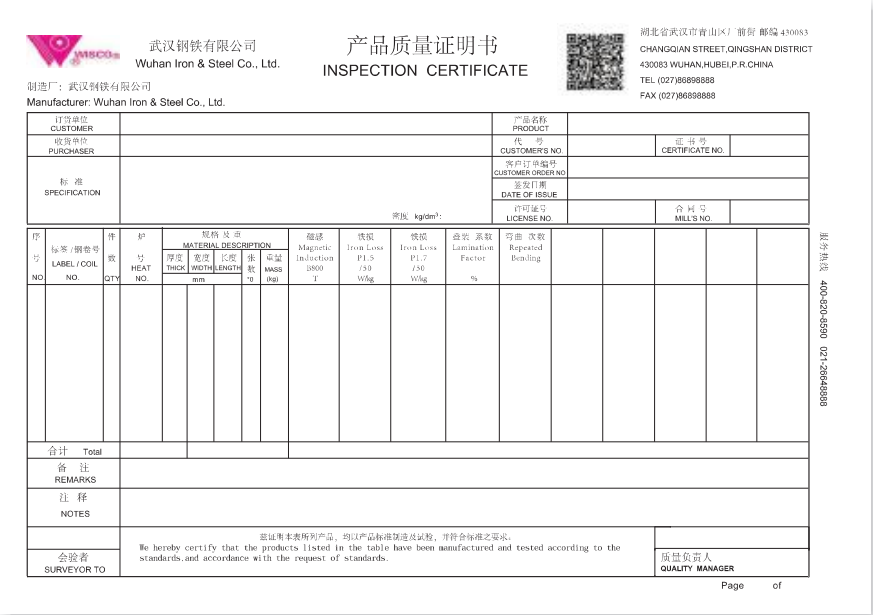

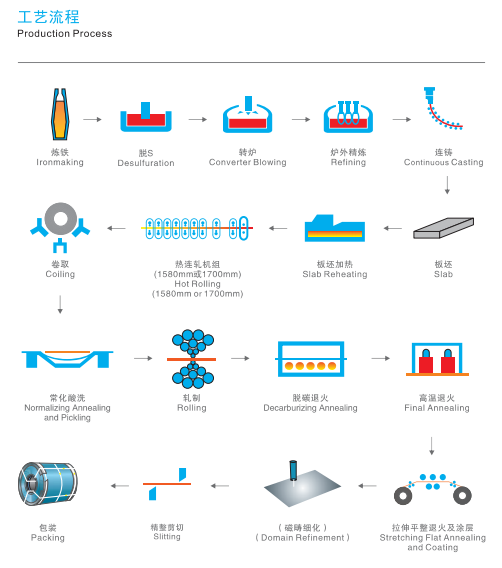

Production Process - Grain-orientedsilicon steel

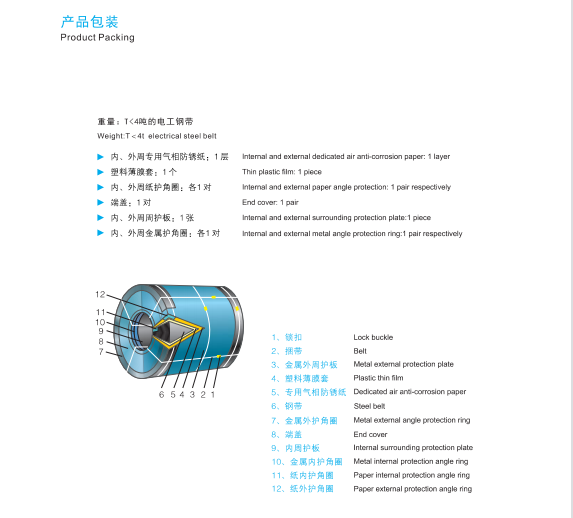

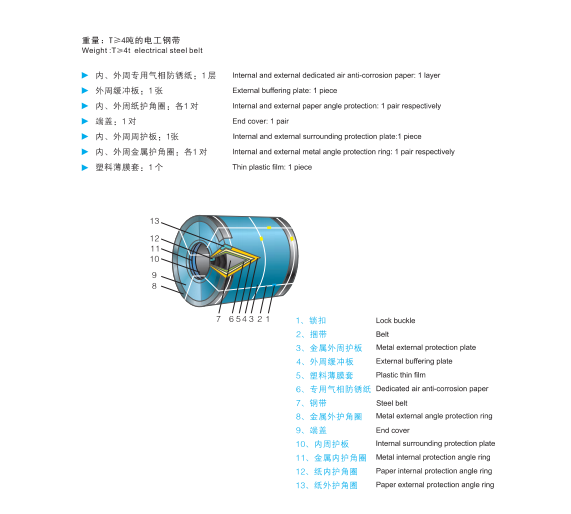

Product Packing

Q&A

Q: What is silicon steel? What is electric steel?

A: Electric steel is magnetically soft material among functional material, and is most wildly used. Generally speaking, silicon steel refers to electric steel with silicon content between 0.5%~6.5% Si. The general electric steel also includes the part that contains little silicon (Si<0.5%). However, nowadays the 2 concepts are not clearly defined, and can be interchangeable.

Q: Classification of electric steel

A: It is roughly classified into hot-rolled electric steel and cold-rolled electric steel. Zhongyuantong steel produces cold-rolled electric steel, which can be further classified into oriented electric steel and non- oriented electric steel.

Q: What is magnetic field?

A: The space field for the acting force between the two magnetic poles is described as magnetic field strength H, the unit is A/m (Ampere/meter). It is the driving primary field produced by external input electric current after the electric steel is made into motor.

Q: Difference between electric steel B50A300 and B50AR300

A: B50A300 is whole processed product. It can be put into use after being purchased or annealing (reducing the loss through stress relief and construction perfection). But B50AR300 must go through annealing before use.

Q: Difference between whole processed silicon steel and semi- processed silicon steel

A: The target of whole processed non-oriented silicon steel annealing is to achieve targeted magnetic property (guarantee value), with the consideration of mechanical property required by stamping and the surface coating. The target of semi-processed product annealing is to achieve the mechanical property required by stamping. The manufactured magnetic property is so poor that the user has to do annealing and bluing to the magnet core so as to achieve the required magnetic property and surface insulation. There can be coating on the semi-processed non-oriented electric steel (applied in Japan market) or no coating (applied in American market, CRML).

Q: Influence of electric steel hardness on product process property![]()

A: The mechanical property of the material has direct influence on the processing property. Various electric steel materials are used in various industries according to their characters. Processing mold and mold adjustment are critical to processing property. Zhongyuantong steel maintains the stability of product mechanical property and guarantees the user’s processing property.

Q: How does Zhongyuantong inspect the hardness of silicon steel material?![]()

A: According to the silicon steel character (thickness, material), Zhongyuantong steel inspects with HV1 standard. There is no conversion relation between Vickers Hardness, Brinell Hardness, Rockwell Hardness, and other Hardness, but there is empirical reference.

Scan To Wechat